Efficiency Gains and Cost Reductions

One of the biggest benefits companies see from AQM is getting more done with less effort. When routine tasks like collecting data and creating reports happen automatically, employees can focus on more important work. For instance, companies using AQM often catch defects right away through real-time monitoring, which means less waste and rework. Some businesses report cutting their quality-related costs in half. This frees up money and people for other priorities.Enhanced Customer Satisfaction

Better quality control directly leads to happier customers. By catching and fixing issues before products reach customers, companies deliver consistently better experiences. For example, when quality problems get solved proactively, customers encounter fewer defects and delays. This reliable performance builds the kind of trust that keeps customers coming back.Data-Driven Decision Making

AQM gives companies a clearer picture of their quality performance through detailed data analysis. Rather than just reacting to problems after they happen, teams can spot concerning patterns early and take action. Having solid data also helps leaders make smarter choices about where to focus improvement efforts.Beyond Basic Automation: Building Comprehensive Quality Systems

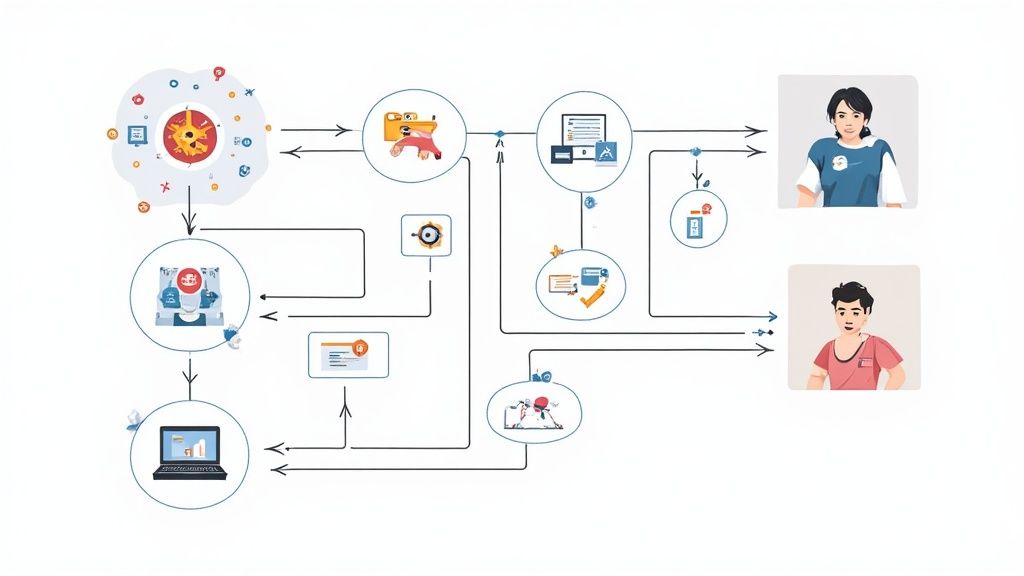

While automation tools are helpful, they're just one piece of the puzzle. Leading companies are creating complete quality systems that combine different technologies - from real-time monitoring to AI-powered analysis tools. By connecting these pieces and following quality best practices, businesses see major improvements in their results. This approach helps build a culture where quality drives growth and success.Building Blocks of Modern Quality Systems

Quality management is evolving from manual checks to integrated automated systems that fundamentally change how organizations ensure and improve quality. Let's explore the key components that make these modern quality management systems effective.

Quality management is evolving from manual checks to integrated automated systems that fundamentally change how organizations ensure and improve quality. Let's explore the key components that make these modern quality management systems effective.

Real-Time Monitoring and Advanced Analytics

Gone are the days of periodic quality checks. Modern systems use continuous automated monitoring and analysis to catch issues instantly. For example, in manufacturing, sensors track metrics like temperature, pressure, and output in real-time. When measurements deviate from acceptable ranges, the system immediately alerts operators so they can address problems before defects occur. Beyond just monitoring, these systems analyze patterns over time to highlight opportunities for process improvements.The Power of AI-Driven Investigation Tools

When quality issues arise, AI tools can quickly analyze vast datasets to identify root causes much faster than manual investigation. AI systems process everything from production logs to customer feedback, pinpointing exactly what went wrong. This targeted approach helps teams implement precise fixes while minimizing downtime. For instance, if customers report a product defect, AI can trace it back through manufacturing data to find the source of the problem.Centralized Data Warehouses: Unlocking Actionable Insights

A central data warehouse acts as the hub connecting information from every part of operations - from the production floor to customer service. By bringing all this data together, companies gain complete visibility into quality across their business. Insights from one area directly inform improvements in others. Recent market projections show growing adoption, with the North American automated quality management software market expected to reach $2.52 billion by 2028.Proactive Quality Management Through Pattern Recognition

Rather than just reacting to problems, modern systems use AI to spot patterns that often precede quality issues. This allows organizations to prevent problems before they impact customers. The combination of pattern recognition, real-time monitoring, and AI investigation creates a quality ecosystem focused on prevention rather than reaction. While implementing these systems requires careful planning and ongoing refinement, the results are worth the effort. Let's explore the key implementation challenges and proven solutions in the next section.Navigating Successful Implementation

Successfully implementing automated quality management (AQM) requires careful planning and execution. Getting it right means paying attention to both technical requirements and the human elements that drive adoption and success. Let's explore the key factors that help organizations implement AQM effectively.

Successfully implementing automated quality management (AQM) requires careful planning and execution. Getting it right means paying attention to both technical requirements and the human elements that drive adoption and success. Let's explore the key factors that help organizations implement AQM effectively.

Building a Solid Technical Foundation

Just like constructing a house starts with the foundation, implementing AQM begins with establishing the right technical infrastructure. This means more than just buying software - you need to ensure your systems can work together smoothly. A central data warehouse forms the backbone, collecting information from different sources that AQM tools need to function. For instance, production data must flow seamlessly between your CRM software and quality management systems. Without proper integration, even the best AQM tools won't have access to the data they need to be effective.Empowering Your Team Through Training

Good training makes the difference between success and struggle with new AQM tools. Your team needs to understand both the practical aspects of using the software and the reasons why it matters for their work. When people see how AQM can make their jobs easier and more meaningful, they're more likely to embrace it. Regular training sessions and ongoing support help reinforce these learnings. This investment pays off through increased confidence and better results as your team makes the most of the AQM system.Fostering Employee Buy-In

Change often meets resistance, especially with new technology. The key is to address concerns openly while highlighting specific ways AQM benefits each role. Show your team exactly how automated reporting saves time and provides better insights for decision-making. Include employees in the implementation process by asking for their input and recognizing their contributions. When people feel ownership over the change, they're more likely to actively support it.Maintaining Momentum and Driving Continuous Improvement

Implementing AQM isn't a one-time project - it requires ongoing attention and refinement. Success depends on regularly checking how well the system works and making adjustments based on results and feedback. Track important metrics and gather input from users to identify areas for improvement. This helps ensure your AQM system keeps delivering value as your business grows and changes. By staying focused on continuous improvement, you can maximize the benefits of automation while keeping your quality management practices effective and up-to-date.Maximizing Returns Through Data-Driven Decisions

Smart companies use automated quality management (AQM) systems to do more than just improve processes - they use them to drive real business growth. By analyzing data from these systems, organizations can spot problems early and find new ways to boost performance, rather than just reacting when issues come up.

Smart companies use automated quality management (AQM) systems to do more than just improve processes - they use them to drive real business growth. By analyzing data from these systems, organizations can spot problems early and find new ways to boost performance, rather than just reacting when issues come up.

Calculating the ROI of Automated Quality Management

To show the true value of AQM, you need to look beyond the upfront costs and measure its long-term financial impact. Here's a practical framework to calculate the return on investment:- Reduced Quality Costs: AQM helps catch defects early through real-time monitoring, cutting expenses from rework, returns, and warranty claims. Many companies report 50% lower quality-related costs after implementation.

- Increased Productivity: When routine tasks are automated, employees can focus on more valuable work. According to McKinsey & Company research, this leads to 20% higher efficiency.

- Enhanced Customer Satisfaction: Better product quality means fewer defects, which keeps customers happy and loyal. This often results in more referrals and repeat business.